4000 Series disc brake rotors are a direct replacement single piece brake rotor, designed for drivers seeking upgraded performance braking above and beyond standard OE levels.

Cast from high carbon alloyed iron and undergoing Thermal Stability Profiling, DBA’s metallurgy can handle the increased stress and heat generated under intense braking applications, time and time again.

Featuring DBA’s Kangaroo Paw ventilation that implements a series of 144 diamond and teardrop patterned pillars, DBA achieves up to a 30% increase in surface area and 20% improvement in cooling efficiency (as compared to a traditional straight vane design).

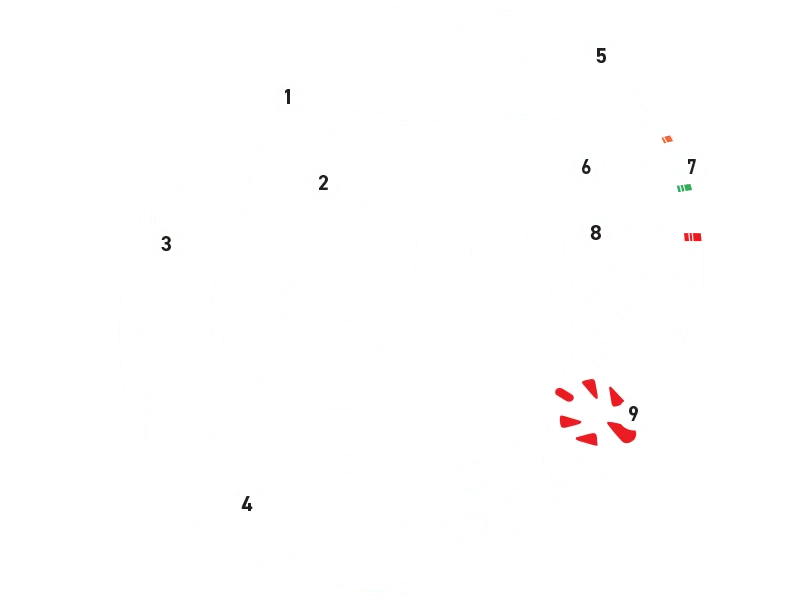

Features

SURFACE DESIGN – 1

Symmetrical slots and/or chamfered drill holes facilitate the exit of friction dust and gasses, for a quieter and more responsive pedal feel.

ANTI RUST – 2

Painted non-friction areas to prevent rust and enhance appearance, or full En-shield coating to protect the rotor and alleviate the need for pre-installation cleaning.

BI DIRECTIONAL USE – 3

Symmetrical slotting and/or drilling for universal left/right use.

THERMAL STABILITY PROFILING – 4

Heat treatment cycles realign the microstructure of the iron, resulting in increased rotor stability and durability.

THERMAL EFFICIENCY – 5

Centre split core castings for increased heat transfer and thermal efficiency.

CBN – 6

CBN (Cubic Boron Nitride) machine turned finish, minimising disc thickness variation and the potential for pad “knock” and resulting premature wear.

THERMOGRAPHIC HEAT PAINT – 7

Paint markings change colour at specific temperature thresholds to assist with the monitoring of braking temperatures and rotor fatigue.

HIGH CARBON ALLOYED IRON – 8

Formulation allows for optimal interaction with DBA’s thermal stability profiling (TSP). Increases the capacity of the rotor to handle constant and extreme heat over prolonged periods.

KANGAROO PAW – 9

Unique Kangaroo Paw vane design for up to 20% better heat dissipation, increasing braking effectiveness and prolonging brake life.

*Some variants may not contain all features

Variants

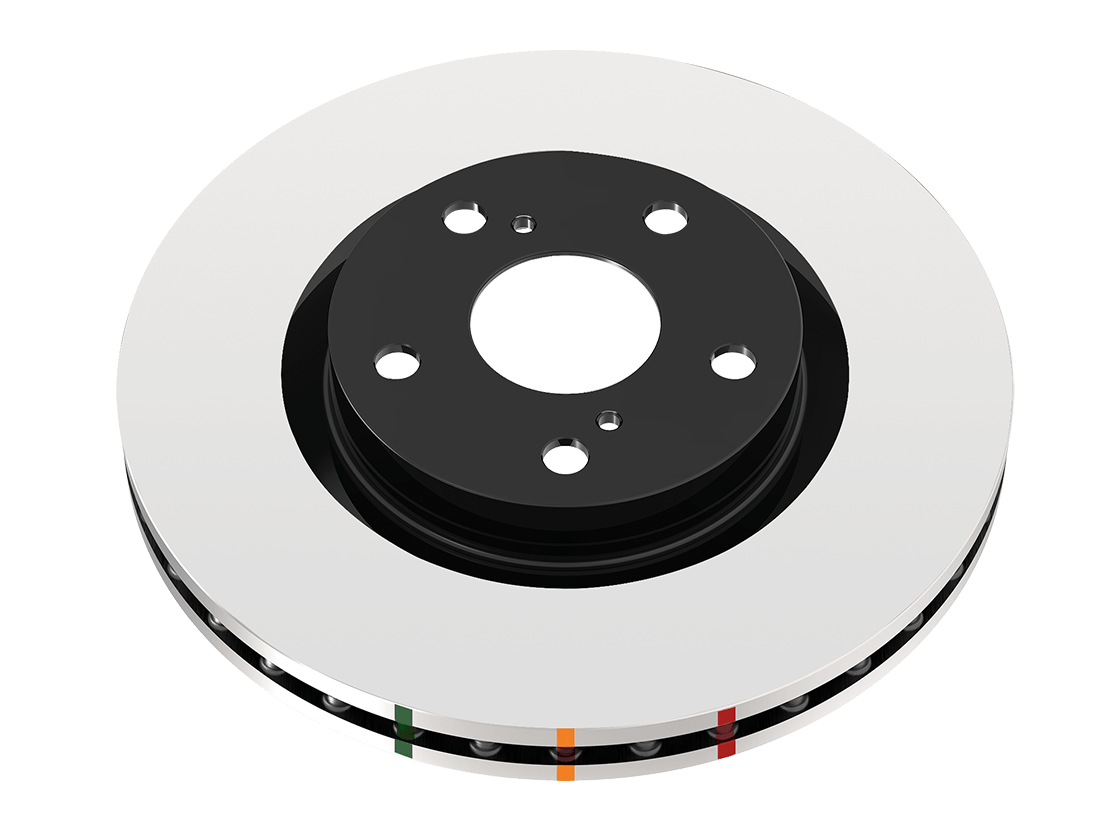

HD

4000 Series HD variant features a smooth OE style rotor finish, popular for drivers looking for the benefits of a 4000 Series rotor but requiring an OE style look, such as controlled race divisions.

4000 Series HD part numbers are not denoted by any part number suffix.

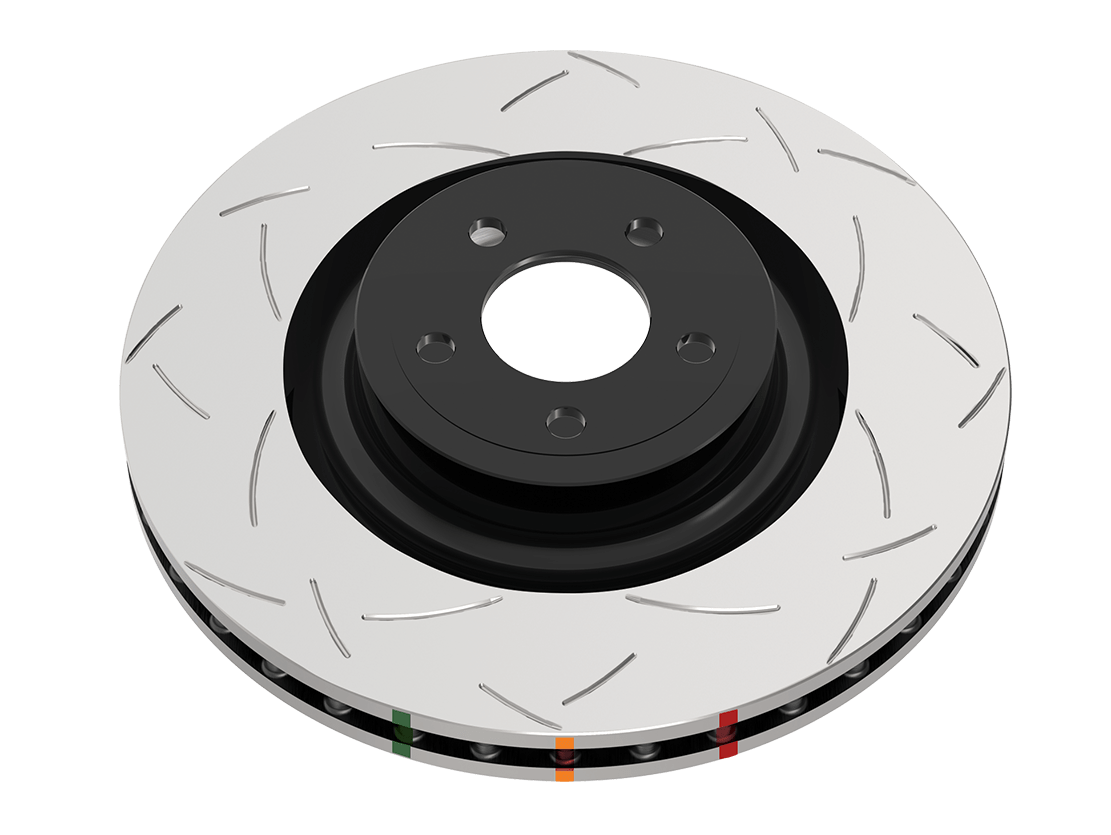

T3

4000 Series T3 is the ultimate in direct replacement single piece performance brake rotors Featuring all the benefits of the 4000 Series plus DBA’s patented world renowned T3 bi directional slot design.

Built on the foundations of DBA’s T2 slot, the T3 slot design features additional, precise, CNC machined tri symmetrical slots, resulting in an even quieter, more responsive and smoother brake pedal feel The T3 slot increases the number of exit points for brake pad friction dust and gases to escape through, further increasing the consistency and effectiveness of every brake stop.

We recommend a T3 slot for high performance applications.

T3 rotors are denoted by the suffix (S) in 4000 Series part numbers.

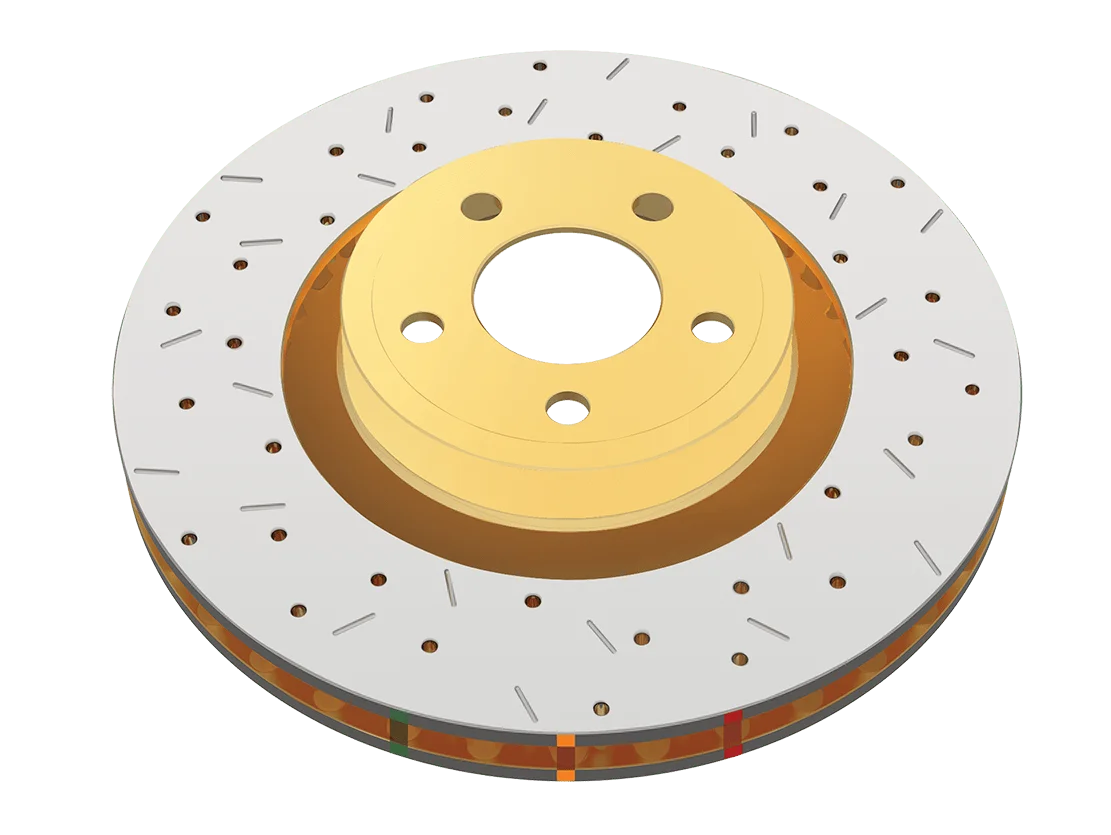

XS Gold

XS Gold provides all the benefits of 4000 Series, with a premium non directional cross drilled and slotted design, plus an attractive gold finish on the rotor hub.

The introduction of our unique cross drilled and slotted design increases the number of exit points, allowing more brake pad friction dust and gases to escape through both the cross drilled holes and slots, resulting in better braking performance.

While providing a similar performance benefit to the T3 slot, the XS Gold is a popular alternative for show cars.

Drilled rotor configurations are not recommended for heavy off-road or track day usage.

XS Gold is denoted by the suffix (XS) in 4000 Series part numbers.

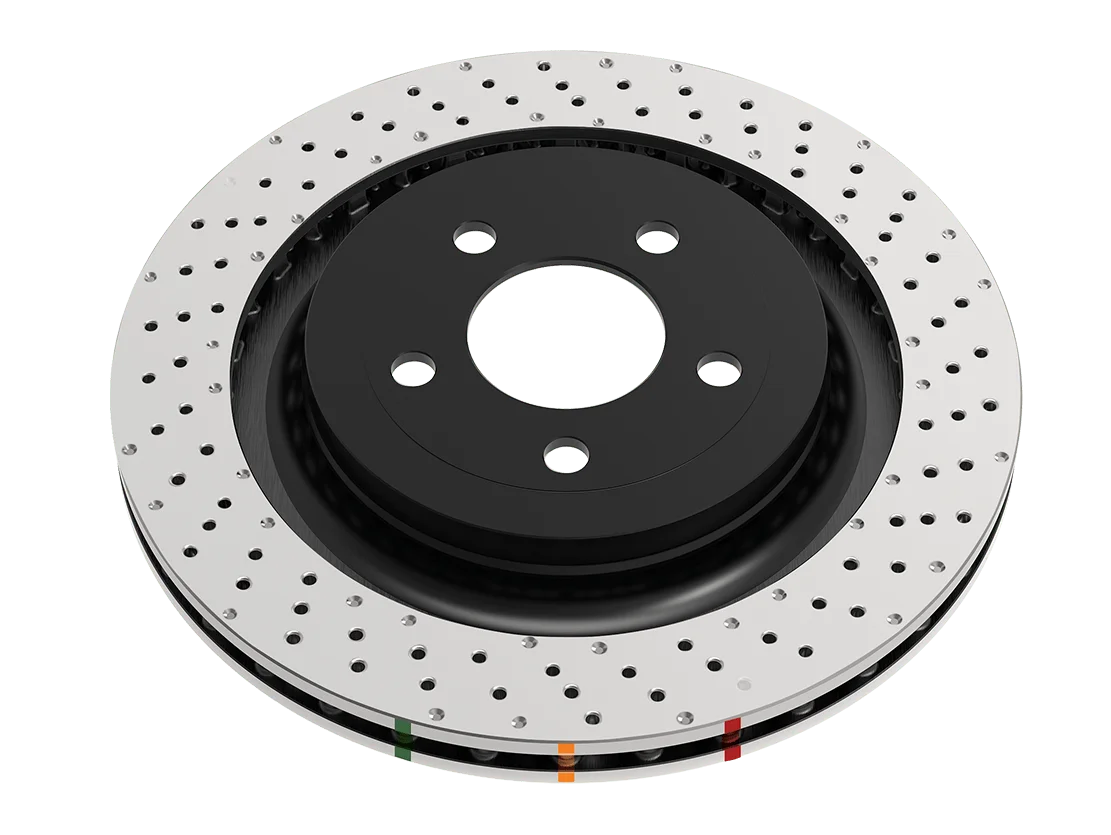

XD

4000 Series XD variant features DBA’s non directional cross drilled and dimpled rotor design.

The XD finish provides additional cooling benefits above the HD spec, along with enhanced sports aesthetics.

The DBA mix of dimples and drilled holes provides enhanced rotor structural support above transitional cross drilled techniques.

Drilled rotor configurations are not recommended for heavy off-road or track day usage.

XD rotors are denoted by the suffix (XD) in 4000 Series part numbers.